From semiconductor shortages to surging logistics costs to a persistent talent gap, global supply chains remain under pressure. Even as some markets stabilize, ongoing volatility driven by geopolitical tension, inflation, climate-related disruptions, and shifting consumer behavior continues to test procurement teams and supply chain leaders. As organizations adapt to new ways of working and navigate growing uncertainty, the need for resilient, risk-aware supply chains is more important than ever. Implementing the six strategies below can help safeguard your supply chain from future disruptions and strengthen your overall readiness.

1. Diversify your supply base

According to McKinsey’s 2024 Global Supply Chain Survey, companies with diversified sourcing saw 35% less disruption than those relying on single regions or partners. A diversified supplier base is your first line of defense against disruption. Start by maintaining an Approved Supplier List that is regularly reviewed and stratified by geography, ownership type (e.g., minority- or women-owned businesses), and risk exposure. This level of insight helps reduce over-reliance on any single supplier or region. For sole-sourced categories, consider launching a competitive sourcing event or dual-sourcing strategy. Engage your Third-Party Risk Management function early in sourcing events to evaluate prospective partners. And conduct regular supply base risk assessments to proactively identify where suppliers themselves may be vulnerable.

2. Enhance supplier governance

Strong supplier governance builds more resilient partnerships. During negotiations, ensure a shared understanding of goals, and put KPIs or SLAs in place to measure performance. Set expectations for regular business reviews and use them to address issues before they become problems. These reviews should be both strategic and tactical, providing opportunities to collaborate on solutions, resolve bottlenecks, and plan for contingencies.

3. Rationalize every dollar

In an inflationary environment, reactive spending can lead to serious budget inefficiencies. Instead of using prior-year budgets as baselines, develop a should-cost model that reflects current demand and market conditions. Update these models frequently and monitor key input costs closely. This approach equips you to have more informed pricing discussions and ensures your sourcing strategies align with business needs, not outdated assumptions.

Tip: Use indexes like the Producer Price Index (PPI) and commodity trackers to inform should-cost models and strengthen negotiation leverage.

4. Empower your talent

Labor shortages and skill mismatches continue to impact procurement and supply chain functions. Retention is just as important as hiring. Identify where your team may have skill gaps and invest in upskilling or cross-training programs. Emphasize flexibility, career progression, and purpose-driven work, especially for younger professionals who value meaningful contributions. Empowering your team with modern tools and data access also drives engagement and performance.

5. Obtain end-to-end data visibility

Without visibility into supplier operations and inbound data, you’re flying blind. Disruptions anywhere in your supply chain can ripple downstream. Integrate supplier data into your ERP or supply chain control tower to improve forecasting, manage inventory, and prevent costly delays or order expedites. Real-time visibility also enhances your ability to respond to shifts in customer demand or supplier performance.

6. Consider a technology assessment

Supply chain technology has advanced rapidly in recent years. Now’s the time to assess whether your current tech stack meets the evolving needs of your organization. Tools like lifecycle management platforms, e-sourcing solutions, and procure-to-pay (P2P) automation systems can unlock new efficiencies, reduce manual errors, and elevate procurement’s role as a strategic business partner.

Tip: Consider a phased implementation to minimize disruption, starting with lower-risk categories or pilot teams to test ROI.

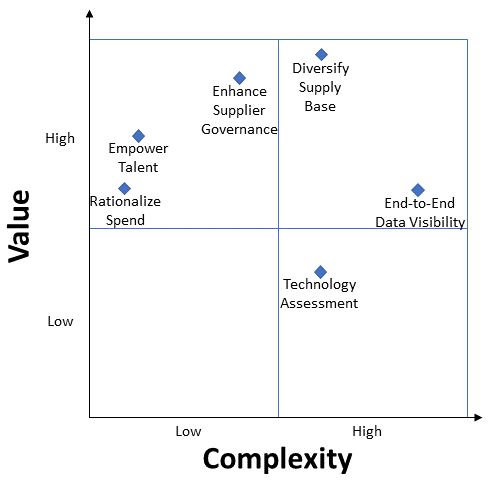

The graphic below shows the relationship between value and complexity for each of these initiatives. We recommend starting with strategies that offer high value with low to medium complexity, typically enhancing supplier governance, empowering talent, and rationalizing spend. These foundational actions not only deliver quick wins but also prepare your team to tackle higher-complexity initiatives like supply base diversification and digital transformation.