The COVID-19 pandemic affected the ability to procure a variety of necessary goods and services, creating shortages in everyday essentials from toilet paper to computer chips to skilled labor. These disruptions greatly tested the resiliency of our supply chains. With the country beginning to emerge from the pandemic, risks abound as we slowly return to pre-pandemic spending levels and adapt to a new normal. It is therefore becoming exceedingly important to be aware of the risks that face your supply chain upon COVID-19 re-opening. Implementing the six strategies below can help you safeguard your supply chain from these re-opening risks.

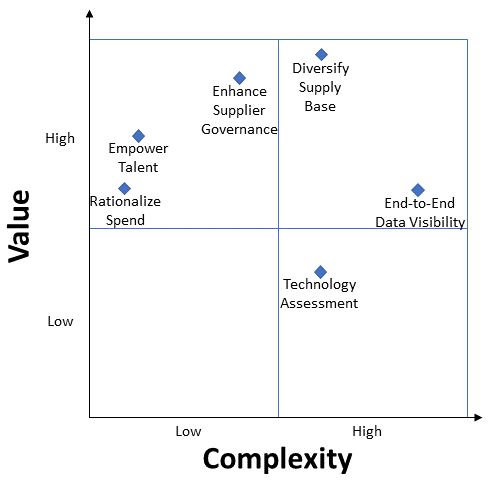

| 1. Diversify your supply base | Value: High | Complexity: Medium/High |

Having an Approved Supplier List with stratification that is regularly evaluated and maintained is the first step to understanding your partners and where associated risks may lie. Vary the geography, size, and ownership type of your suppliers to bolster your network. Consider a competitive sourcing event for any sole-sourced commodities or services. Engage 3rd Party Risk Management as a stakeholder in your sourcing events to carefully screen any new partners. Finally, conduct a risk assessment of your supply base to get ahead of any risks your suppliers may face should their processes be disrupted.

| 2. Enhance supplier governance | Value: High | Complexity: Low/Medium |

The most productive relationships are mutually beneficial. During contract negotiations, ensure all parties have a clear understanding of each other’s goals and establish KPIs and/or SLAs to measure progress against them. Conduct regular business reviews to track progress and to address gaps or concerns. These forums should also serve as opportunities to get ahead of potential bottlenecks or disruptions.

| 3. Rationalize every dollar | Value: High | Complexity: Low |

COVID-19 has greatly affected purchasing habits, so instead of using last year’s budget as baseline, justify every dollar of spend by developing a should-cost model based on future demand with escalation considered to protect against volatility. Update the models regularly and keep a close eye on input pricing. This will allow you to understand adjusted demand levels before making price adjustments. Defining your new target is key prior to addressing price with a supplier.

| 4. Empower your talent | Value: High | Complexity: Low |

With the rising appeal of gig economy work, the onset of the “Great Resignation,” and a competitive hiring market, retaining talent is becoming increasingly difficult. Data shows resignations are at an all-time high and there are more opportunities available for job seekers. To help safeguard your workforce upon re-opening, assess gaps and identify opportunities to upskill/reskill employees to fill gaps. Consider offering return incentives, including remote work, to allow greater flexibility. Finally, consider cross training your employees to bolster contingency plans and to recognize adaptable employees.

| 5. Obtain end-to-end data visibility | Value: High | Complexity: Medium/High |

The volatility of consumer’s rapidly changing purchasing needs during the re-opening increases the threat of greater imbalances between supply and demand. Order data visibility from your suppliers is key to avoiding delays, expedites, or canceled orders. Supplier data can be integrated into your ERP to provide information needed to manage inventory and to reduce supply chain risk.

| 6. Consider a technology assessment | Value: Low/Medium | Complexity: High |

Robust technology is the backbone of a resilient supply chain. Considering the changing needs of your business may help identify gaps that new technology may be able to address. Software, such as lifecycle management tools and procure-to-pay systems, leverage workflow management to streamline tasks and to automate previously manual tasks, which frees up your team’s capacity to focus on more strategic work.

The 4-box graphic below shows the relationship between value and complexity for each of these initiatives. We recommend you consider first the initiatives that deliver the greatest value with the lowest complexity. Want to get started? Contact us to speak to one of our experts today!

Subscribe to ProcureAbility Insights to access whitepapers, presentations, plus our latest thought leadership.