Supply chain disruptions from the global pandemic have challenged procurement teams across many industries. Utilities, however, have been better positioned than most. They rarely relied on just-in-time inventory, allowing them to avoid the worst effects as global supply chains struggled to deliver on time. Grid resilience, recovery efforts, and established regulatory frameworks promoted careful, strategic procurement practices that evolved over time. As a result, utility procurement has seen steady, meaningful change, creating a long-term, sustainable model that historically insulated it from supply chain issues. Nevertheless, it is now clear that utilities are not immune, as shortages of critical materials have become increasingly common.

Tighter alliances balanced with managed diversification

Utility CPOs and procurement teams now face shortages, persistent inflation, and shipping bottlenecks, forcing them to balance supplier alliances with sourcing diversity. Traditionally, the pendulum favored alliances. Procurement teams benefited from committing to a supplier, earning long-term commitments in return. Consolidated sourcing offered clear advantages and efficiencies by leveraging volume. Today, the value of diversification is more apparent than ever, as organizations explore multiple suppliers and strategies to meet their needs.

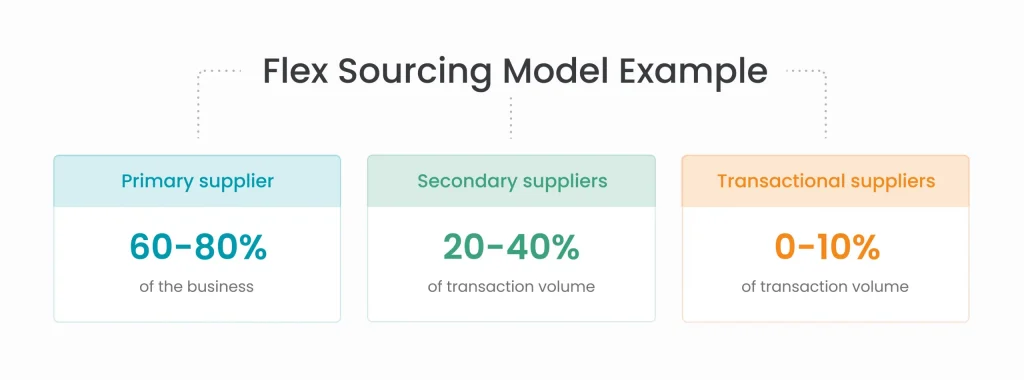

Many clients now use a flex model, such as a 70/30 mix, which keeps alliance suppliers as a core while adding backup suppliers. They also leverage the spot market to test pricing and secure ad-hoc production slots. A flex model does not reduce the value of alliances. Instead, it creates a sourcing mix that adds resiliency and flexibility. When a port closes or a supplier faces raw material challenges, strong procurement relationships enable a seamless shift to alternative sources.

Supplier diversification and resiliency have become even more critical to our industry over the past few years of turmoil amongst the backdrop of global interdependence. Let’s explore an example of a successful flex model implemented to mitigate market and economic uncertainties.

Primary supplier

Your primary strategic supplier, with whom there is a high-level of mutual reliance and potential impact, makes up approximately 60-80% of your business. This is a supplier where both parties are committed to a strong, symbiotic partnership where executive alignment at the highest levels exists and is supported.

Your primary supplier works with you on strategic initiatives, including long-term purchasing commitments. This may involve joint R&D, product development, and collaborative design alternatives, such as lighter materials or different pole mounts. You may also co-develop intellectual property agreements to support supplier capital investments and expanded production capacity in new facilities. As a best practice, utility companies should establish SLAs with suppliers to ensure minimum on-time delivery rates and include a legal option to terminate the agreement if expectations are not met.

In today’s market of constrained materials, alliance relationships are more critical than ever. Some suppliers facing slowdowns from labor or raw material shortages are skipping RFPs or renegotiations. Others are choosing to work exclusively with their alliance partners.

Secondary suppliers

Back-up suppliers comprise 20-40% of your transaction volume. These partners allow you to be flexible with your fluctuating volume needs by providing excess capacity as needed with the security of supplier diversification.

Transactional suppliers

Your remaining suppliers will provide your business with up to 10% of transaction volume by offering both access to spot buys to take advantage of excess market capacity and constant monitoring of the spot market. If there is any disruption with these transactional suppliers, there will be little to no interruption in your supply chain ecosystem.

Utilities’ unique positioning and opportunities

Supply chain challenges often play out differently in the utility industry compared to other sectors. For example, utilities have a history of mutual assistance, sharing crews and equipment during emergencies. A utility recovering from a natural disaster can borrow scarce distribution transformers or other materials from a neighboring utility. This contrasts sharply with industries like healthcare, where companies tightly controlled supplies during crises.

With ongoing supply chain challenges, procurement has grown in importance and often draws the attention of the CEO and Board. Today, supply chain teams have the opportunity to showcase creativity and innovation. They can make an impact across every part of the organization.