The gap between companies that thrive and those that fall behind often comes down to one key factor: how well they plan for uncertainty. Organizations that proactively build business continuity into their procurement strategy, including a structured approach to supplier relationship management, are far better equipped to respond to shifting regulations, fluctuating market demand, and global economic instability. A central element of that preparedness is a resilient supply base, and that begins with resilient, well-managed suppliers.

While executing a sourcing event and awarding contracts to qualified suppliers is an essential first step, it’s only the beginning. Without ongoing engagement, supplier relationships can quickly become transactional and passive, leading to issues such as declining product or service quality, missed compliance requirements, budget overruns or cost creep and poor responsiveness or delivery delays.

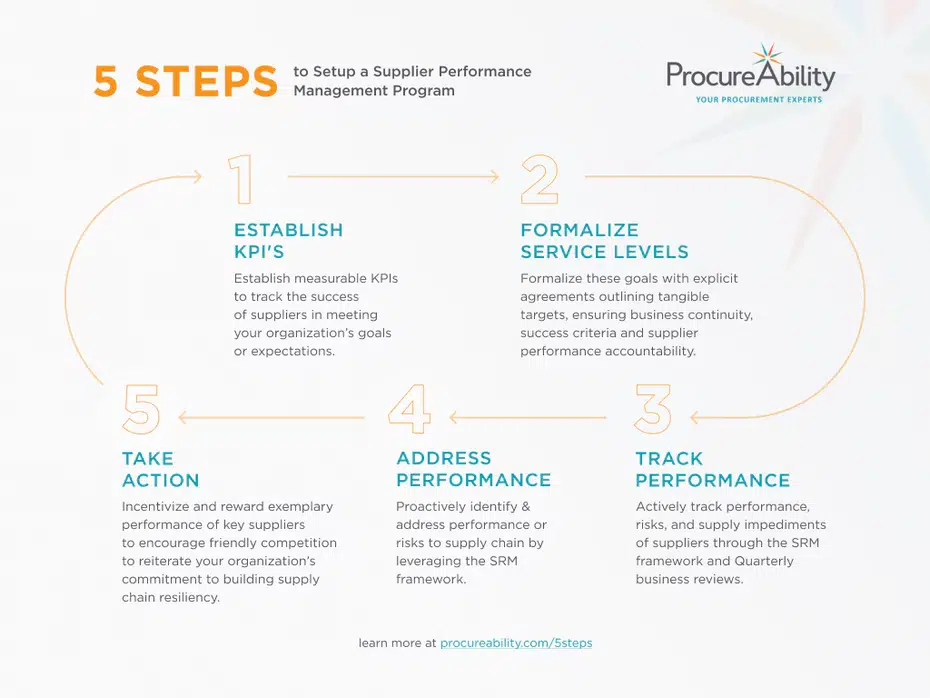

These risks ultimately impact not only your procurement KPIs, but also stakeholder satisfaction and overall supply chain performance. To build a competitive, cost-effective, and resilient supply base, procurement organizations must go beyond the sourcing event and implement a structured Supplier Performance Management (SPM) process. These five key steps ensure that suppliers are consistently meeting expectations and that your organization has the visibility and tools to drive continuous improvement.

1. Establish the Right Supplier KPIs

Begin by identifying the most relevant (KPIs) that reflect your business goals and procurement priorities. These may vary by category, supplier type, or industry, but commonly include:

- On-time delivery

- Order accuracy

- Quality or defect rate

- Compliance with contract terms

- Customer service responsiveness

- Innovation or value-add contributions

Collaborate with internal stakeholders (e.g., Operations, Finance, Engineering) to ensure KPIs reflect organizational needs and are measurable through available data or systems. Clear KPIs lay the foundation for meaningful supplier evaluations.

2. Formalize Service Level Agreements (SLAs)

Once KPIs are defined, incorporate them into Service Level Agreements or performance clauses within supplier contracts. This sets clear, mutual expectations and gives your organization leverage in the event of performance shortfalls.

SLAs should be:

- Specific and measurable

- Tailored by category or supplier risk

- Linked to incentives or penalties

By formalizing service levels early, you establish accountability and reduce ambiguity, making it easier to manage suppliers proactively.

3. Track and Document Supplier Performance

Use supplier scorecards, ERP systems, or third-party procurement platforms to collect and track performance data regularly. Monitoring should include both quantitative metrics (e.g., delivery times, cost variances) and qualitative inputs (e.g., stakeholder feedback, site visit observations).

Tracking performance enables trend analysis across months or quarters, benchmarking between suppliers, and early identification of potential issues. Maintain a historical record of performance to support decisions on contract renewals, supplier development, or re-sourcing.

4. Address Supplier Performance Proactively

Set a regular cadence for reviewing supplier performance – monthly, quarterly, or biannually, depending on the strategic importance of the relationship. Share scorecard results with suppliers in a collaborative format. If performance lags, conduct a performance review meeting and request a corrective action plan. Then align on the root cause and next steps. Open, fact-based conversations reinforce accountability and show suppliers you’re invested in long-term success, not just penalizing mistakes.

5. Take Action to Improve or Exit

If performance does not improve despite intervention, be prepared to take decisive action. Options include:

-

Providing incentives for top-performing suppliers (e.g., increased volume, public recognition)

-

Engaging in supplier development to jointly resolve issues

-

Phasing out or replacing persistently underperforming suppliers

This step reinforces that supplier performance management is an ongoing strategy for driving value, managing risk, and building supply chain resilience.

By following this five-step approach, procurement organizations can turn supplier relationship management into a competitive advantage, improving quality, reducing cost, and building stronger relationships that grow over time.