As we emerge from a global pandemic, there’s a clear line between the companies that prospered and ones that struggled. In order to best support our clients during this “new normal,” we identified the factors of change that are most critical for organizations to understand to help shape their future success. Through extensive research and real-world implementation with clients, we found that In simple terms, companies that anticipate and plan effectively for business continuity can adapt much more rapidly to changes in geopolitical regulations, high volatility in demand, and economic uncertainty. A key factor in supply chain resiliency is being exactly that – a resilient supplier.

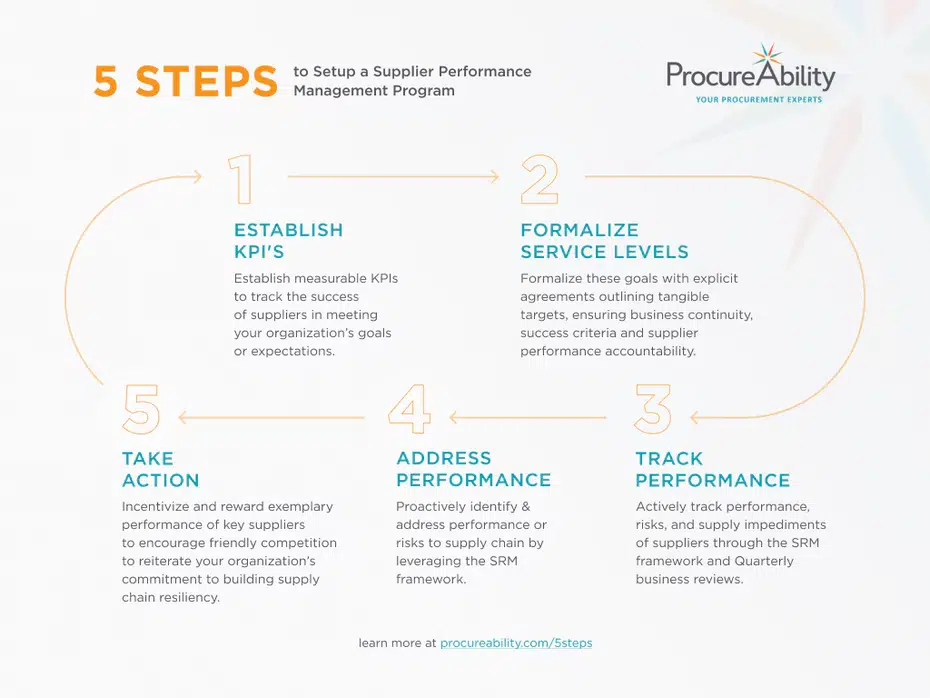

We know that conducting a sourcing event and awarding business to qualified supplier(s) is the first of many, critical steps for any successful Procurement organization. Supplier relationships that are not actively monitored can often lead to complacency, quality & compliance issues, budget overruns, and overall poor performance. This, in turn, can lead to dissatisfied business stakeholders, customers and clients. For these reasons, it is imperative to have a well-defined Supplier Relationship and Performance Management framework. To learn more about the key steps for a successful SRM, we highly recommend that you review our recent insight piece: “Five Steps To Setup A Supplier Performance Management Program.”

The 5 steps to setup a supplier performance management program include:

For more on this topic or to request an assessment of your own SRM program, reach out to one of our Procurement experts!

Subscribe to ProcureAbility Insights to access whitepapers, presentations, plus our latest thought leadership.